Display Options

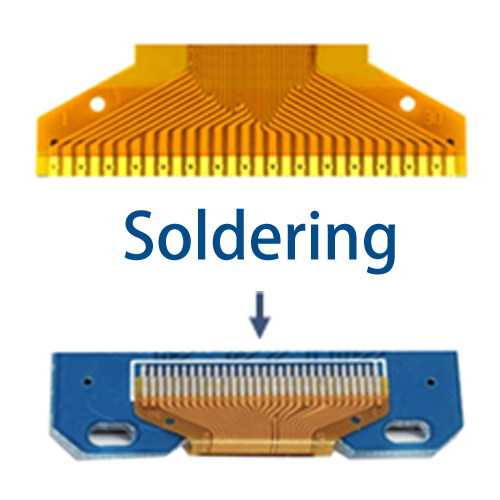

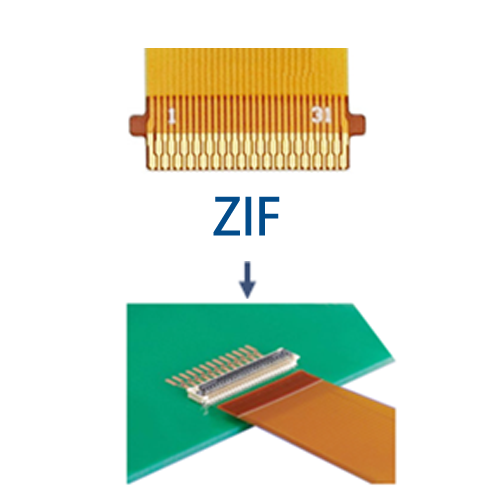

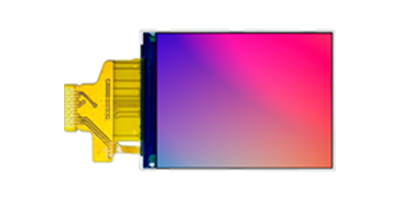

Display and FPC Selection

| Display Type Options |  |

|

|

|

|---|---|---|---|---|

| Display Mode | Emissive (OLED) | Transmissive (TFT) | Transflective (TFT) | Reflective (TFT, EPD) |

| Display Operation | Self-illuminating | Requires Backlighting | Uses Backlighting and Ambient Light | Uses Ambient Light |

| Visibility | Good Indoors | Good Indoors | Good Indoors and Outdoors | Good Outdoors |

| Power Efficiency | Higher | Lower | Moderate | Higher |

| Display Quality | Good Color Contrast | Good Color Contrast | Moderate Color Contrast Indoors | Good Color Contrast Indoors |

| Ambient Light | Less Visible in Bright Environments | Less Visible in Bright Environments | Visible in Various Lighting Conditions | Visible in Bright Environments |

| Outdoor Performance | Poor | Poor | Moderate | Excellent |

| Major Applications | Indoor Display Devices, Wearables | Indoor Display Devices, Wearables | Portable Devices, Outdoor Wearables | E-tags, Wearables, Outdoor Displays |

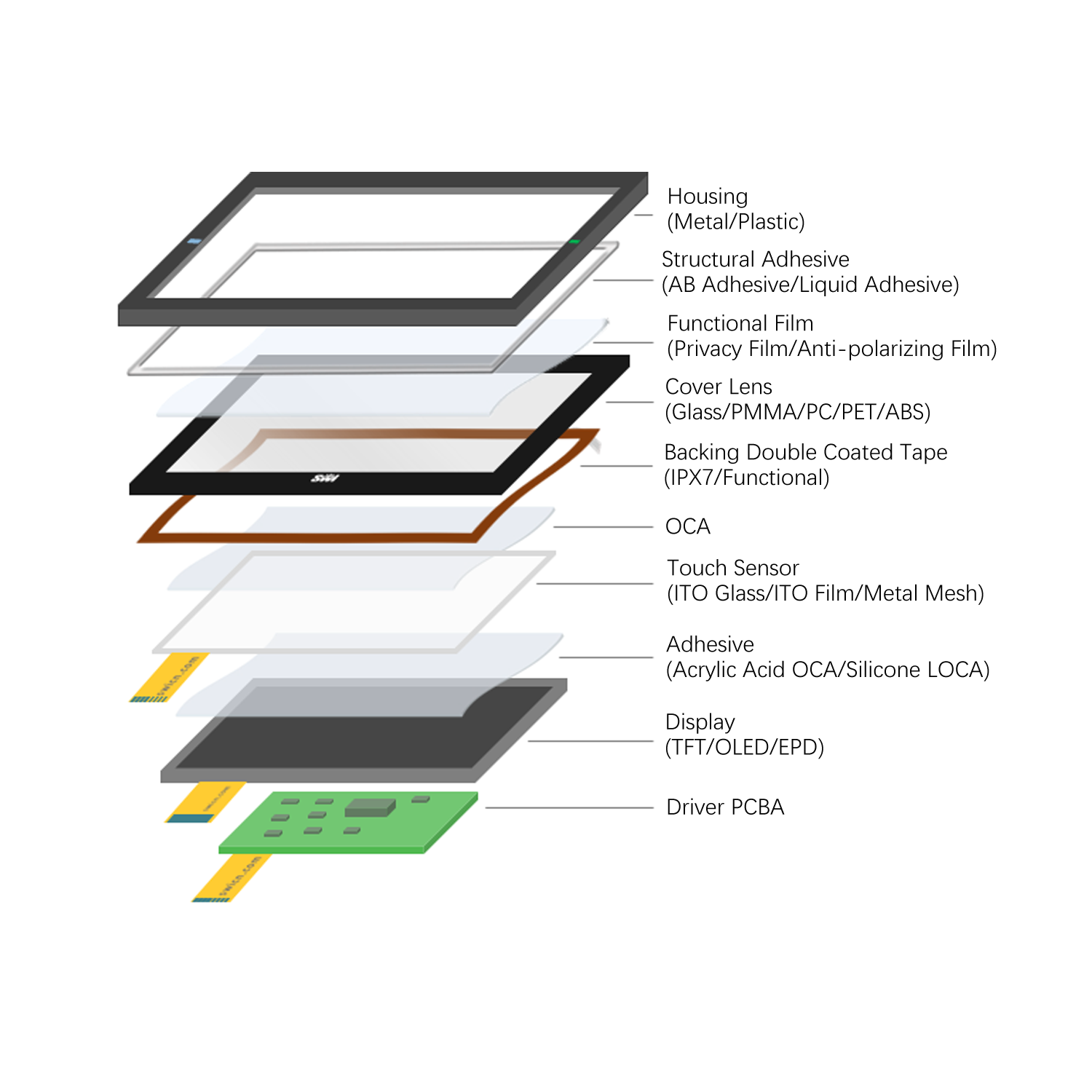

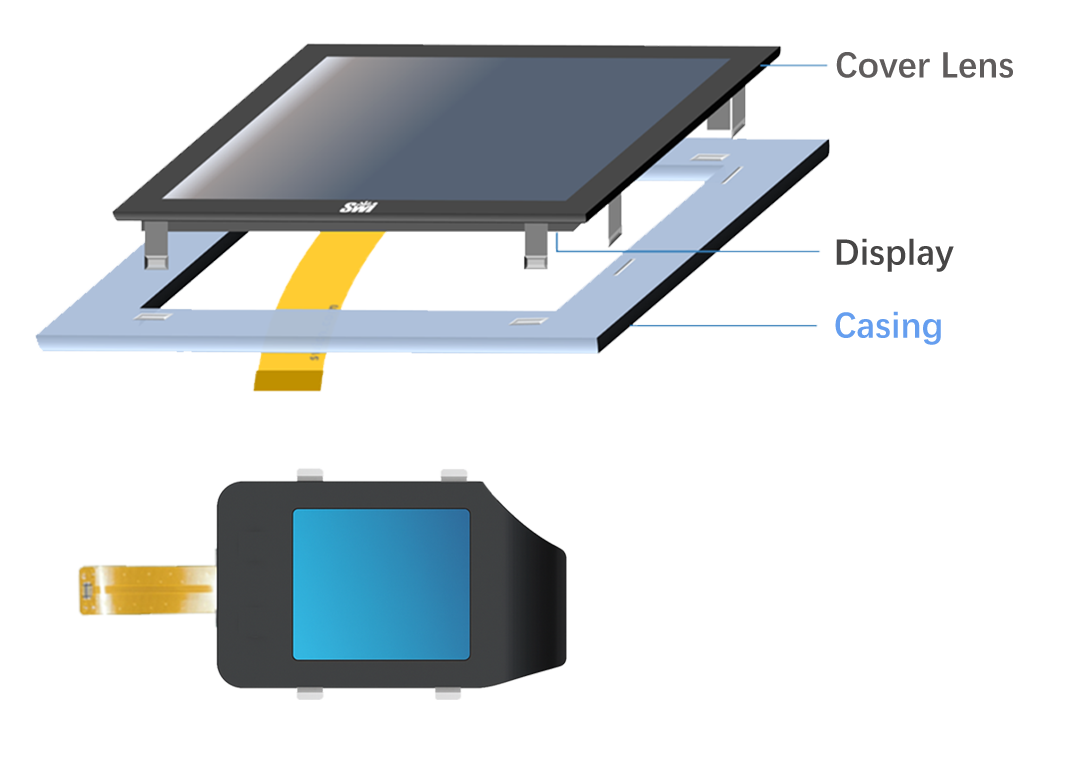

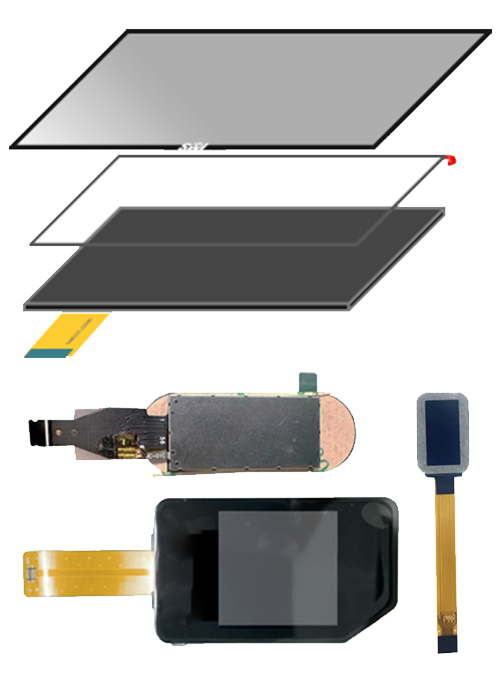

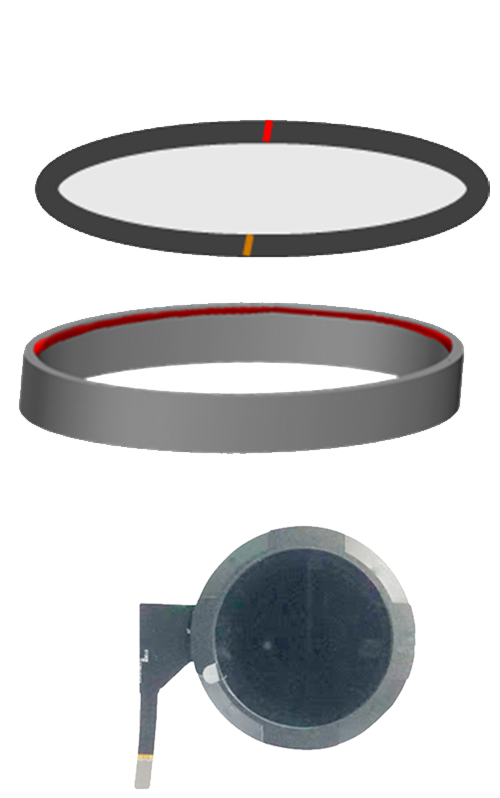

Lamination Options

Optical Full Lamination

Better Optical Quality (clarity, brightness, contrast)

Stronger Impact Resistance

Better Dust and Water Resistance

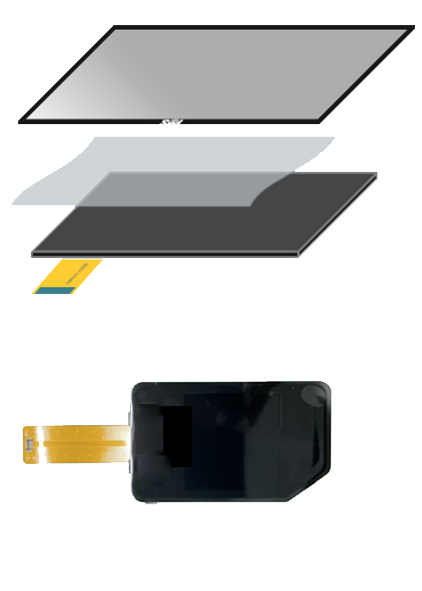

OCA Lamination

- (Optical Clear Adhesive) Easier Processing (clean application with OCA sheet) Lower Cost Lower Reliability for Uneven Surface

LOCA Lamination

- (Liquid Optical Clear Adhesive) Harder Processing (difficult residue clearance) Higher Cost Better Reliability for Uneven Surface

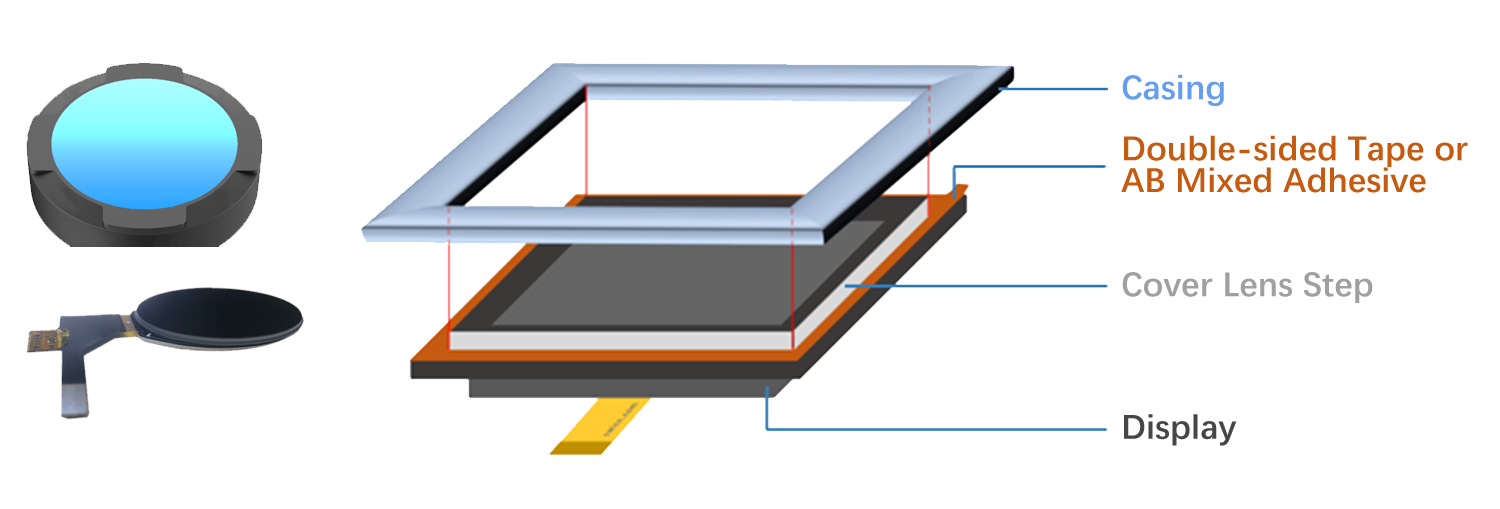

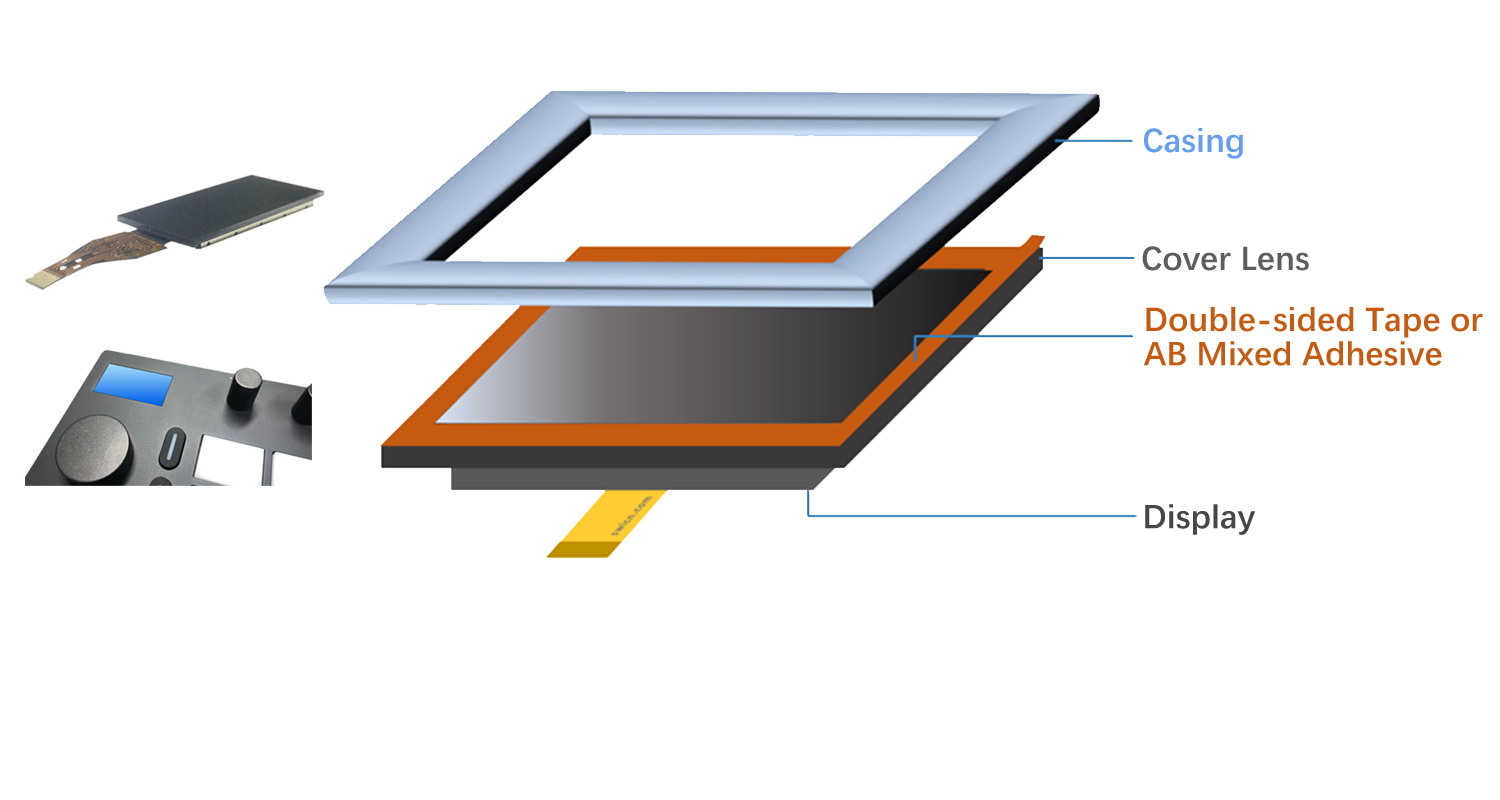

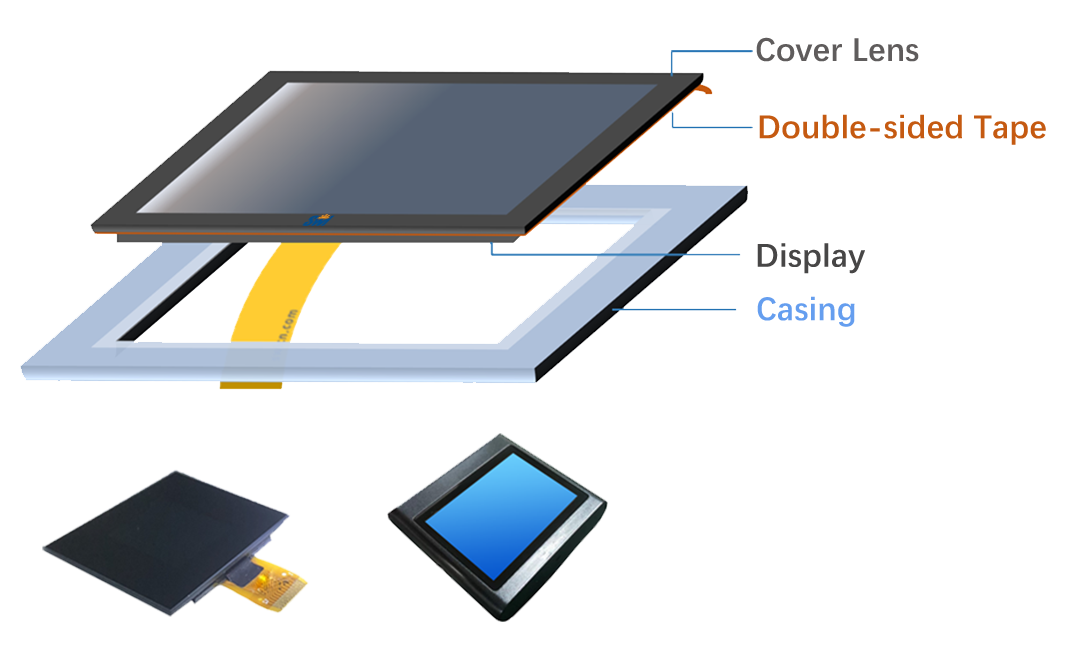

Structural Lamination

Lower optical quality (clarity, brightness, contrast)

Weaker Impact Resistance

Weaker Dust and Water Resistance

Lower Processing Efficiency

Frame Lamination

- Harder Processing (hard to hold frame tape) We can also pre-apply double-sided tape (waterproof if necessary) to the back of the laminated cover glass, allowing assembly workers to easily secure the cover glass to the final product.

Gluing Lamination

- We can customize our adhesive bonding solutions to meet client specifications, using different types of adhesives to assemble the cover lens or housing precisely as needed.

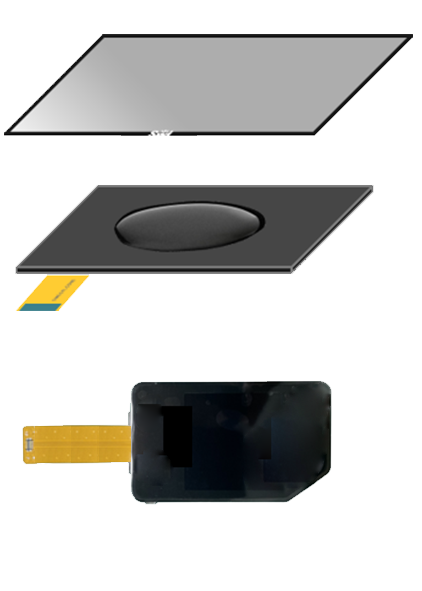

Film Lamination

- To meet our customers' demands for higher optical performance, we apply specialized films to the cover glass including: AG Film (Anti-Glare) AF Film (Anti-Fingerprint) Privacy Film Anti-polarizing Film